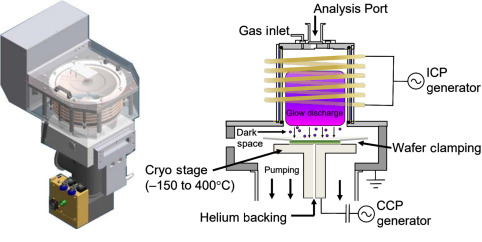

The operational cost of using plasma cleaning systems are low, while providing the highest quality in cleaning surfaces. Another benefit of using a plasma cleaning system is that it eliminates the need to use chemical solvents.

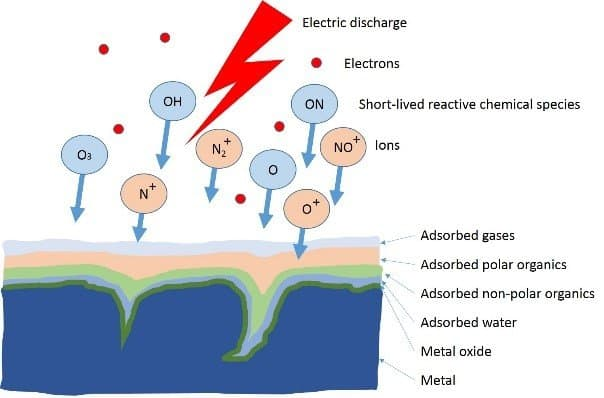

Ultra fine cleaning of surfaces with cold atmospheric pressure plasmas is a process of removing organic, inorganic and microbial surface contaminants, as well as strongly adhering dust particles. It is highly efficient and at the same time very gentle to the treated surface. At higher strength, it can remove weak surface boundary layers, cross-link surface molecules and even reduce hard metal oxides. Plasma cleaning promotes wettability and adhesion enabling a wide spectrum of industrial processes preparing surfaces for bonding, gluing, coating and painting. While being performed using air or typical industrial gases including hydrogen, nitrogen and oxygen, it avoids wet chemistry and expensive vacuum equipment, which positively affects its costs, safety and environmental impact. Fast processing speeds further facilitate numerous industrial applications.

As a result, using plasma cleaning eliminates the need for storage facilities or for making arrangements for solvent waste disposal. Plasma is a proven and effective method for critical surface preparation.

Types of plasma cleaning:

-

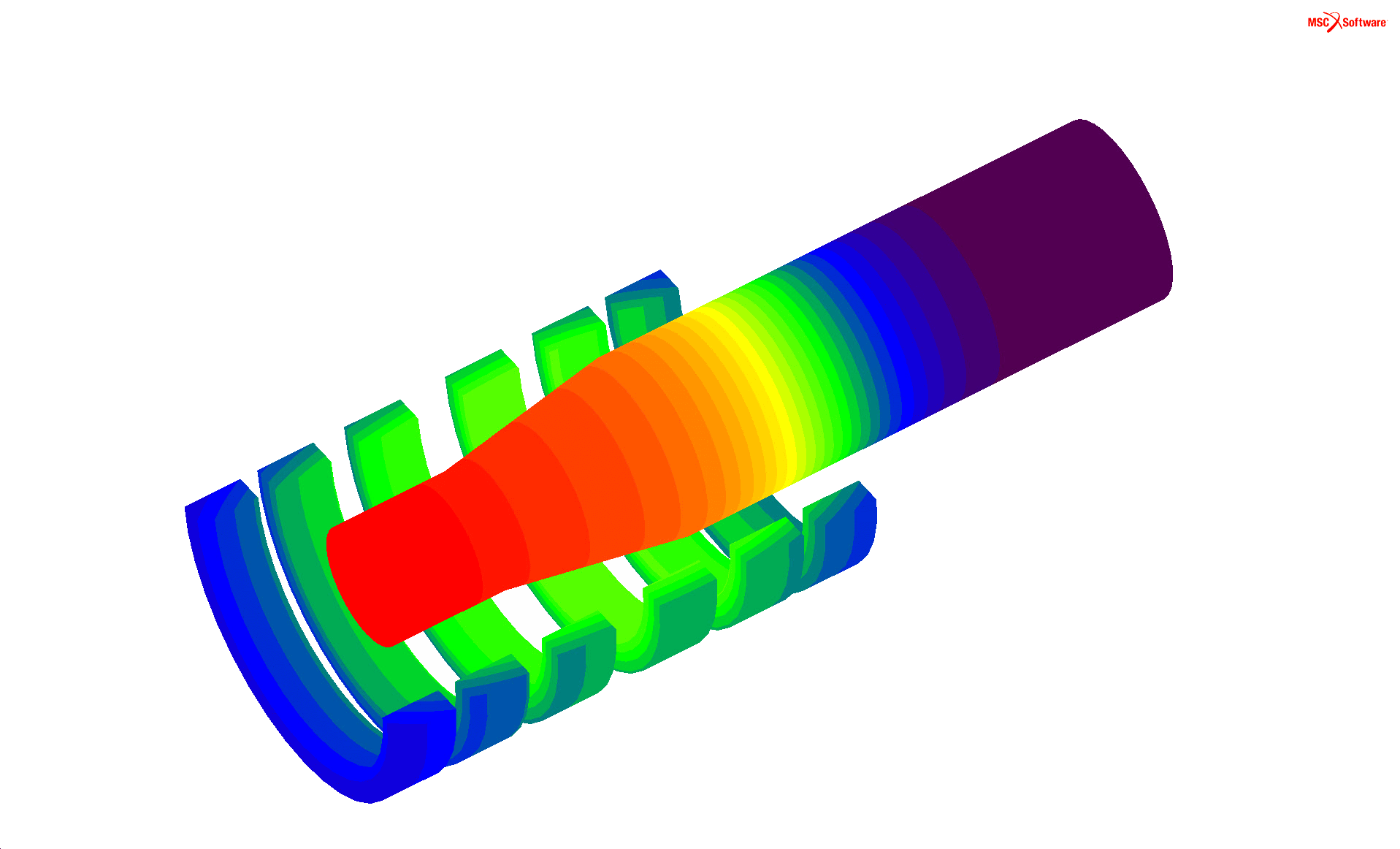

▶ Oxygen-Based Plasma Cleaning

-

▶ Hydrogen-Based Plasma Cleaning

-

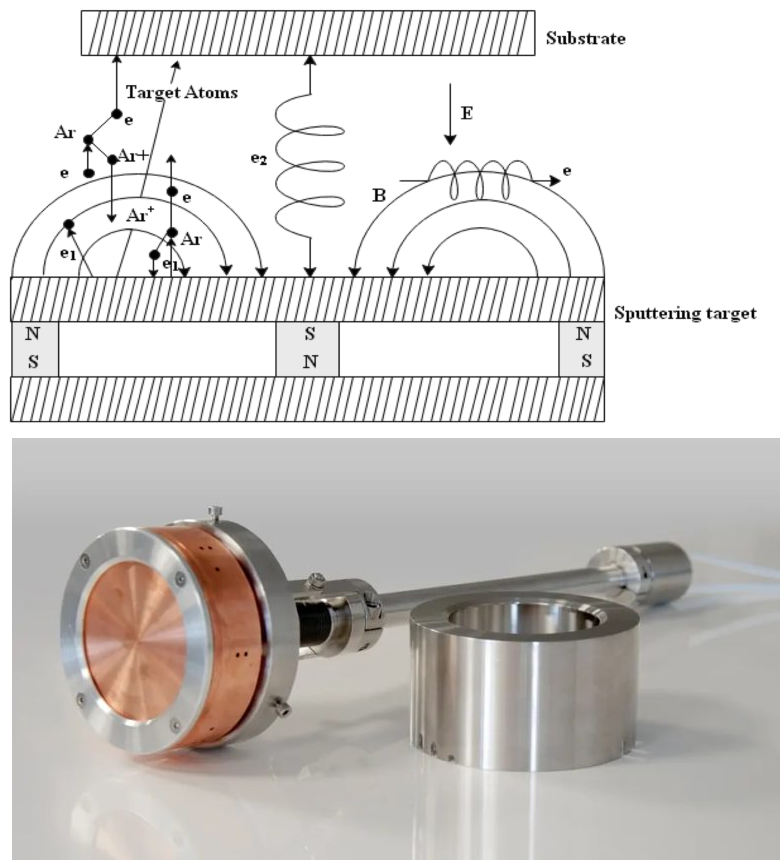

▶ Argon-Based Plasma Cleaning